Driven by modern technology,

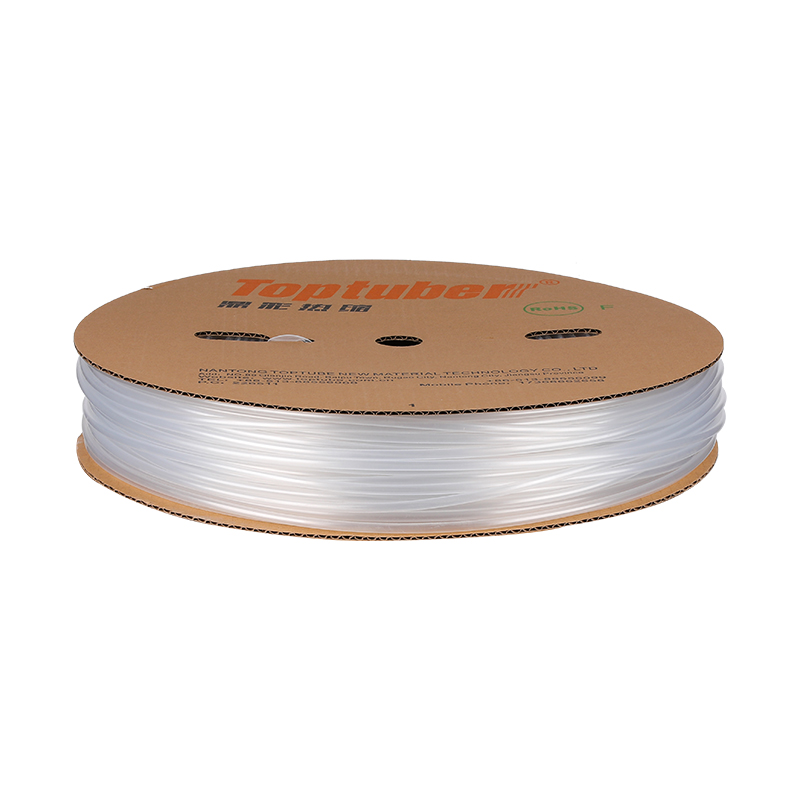

transparent heat shrinkable sleeve are rapidly emerging and becoming an indispensable part of all walks of life. Have you ever wondered how these clear sleeves shrink? Today, we're taking a look at the shrinking process of clear heat shrink tubing and the key factors that influence its performance. Let’s embrace this journey of technological wonders about shrinkage together!

The shrinking process of clear heat shrink tubing results from a unique design in the material. These sleeves are usually made from a polyolefin material that contains a magical substance called heat-shrinkable resin. When these sleeves are exposed to a heat source, the resin inside begins to change, going through a wonderful process from high temperature to low temperature. This change not only makes the casing transparent, it also causes the unique effect of shrinking it. It's like a little magic show in the world of technology, and it's amazing.

However, achieving this magical shrinkage process is not easy, and there are many factors that play a key role behind it. First, temperature is one of the key factors that determines the shrinkage performance of the casing. Different transparent heat shrinkable sleeves have different sensitivity to temperature, so reasonable control is required according to the specific materials when used. In addition, the size and wall thickness of the casing will also affect the shrinkage effect, so the casing needs to be accurately matched according to actual needs when selecting the casing. These factors are like adjusting the various elements in a magic spell and are related to the success of the entire performance.

This shrinking wonder doesn't stay in the laboratory, but has found widespread applications in the real world. Transparent heat shrinkable sleeves are widely used in electronic equipment, automotive industries, and communications fields to provide effective protection and isolation for products. In electronic equipment, these sleeves can effectively prevent the intrusion of moisture and dust, ensuring the reliability of the equipment. In the automotive industry, they are used for cable protection and improve the durability of the entire vehicle system. These real application scenarios are like a stage for casing, showing the powerful charm of the miracle of shrinkage in real life.

In this technological journey around transparent heat shrink tubing, we explore the fascinating science of its shrinking process and the important factors that influence its performance. These ferrules are not only essential tools in the world of technology, but they are also a manifestation of a little magic in the real world. Through the continuous development of technology, our lives have become more convenient and interesting. I believe that in the future, transparent heat shrinkable sleeves will continue to bring more miracles to all walks of life and inject more technological magic into our lives.

中文简体

中文简体

English

English