If you’ve ever found yourself struggling with messy cables, repairing electronic gadgets, or organizing your DIY projects, then heat shrink tubing might just be the magic solution you’ve been looking for. This versatile material has become an essential tool for DIY enthusiasts, electricians, and engineers alike. In this article, we’ll explore the wonders of heat shrink tubing, its practical applications, and how it can revolutionize the way you approach your projects.

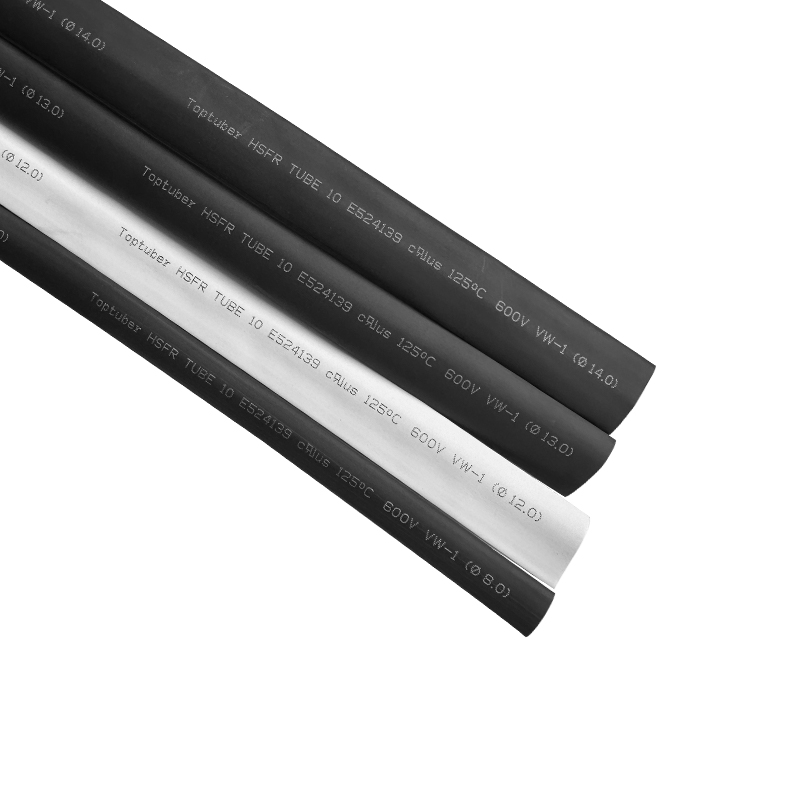

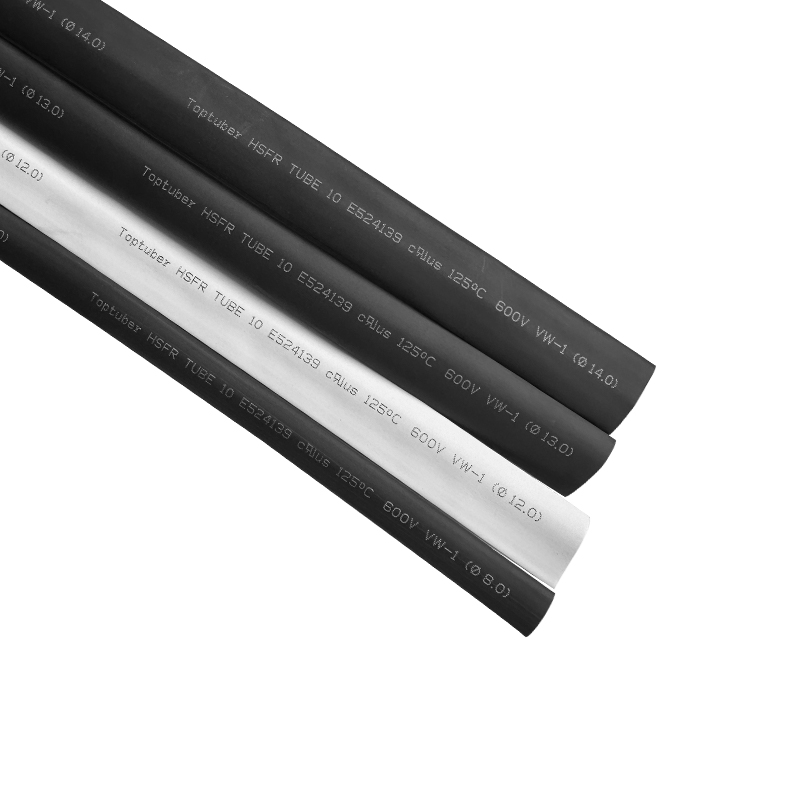

What exactly is heat shrink tubing? Imagine a magical material that, when heated, shrinks down to a fraction of its original size, conforming to the shape of whatever it’s covering and creating a protective, insulating layer. This is the essence of heat shrink tubing. Typically made from polyolefin, it comes in a variety of sizes, colors, and shrink ratios to accommodate different needs. Whether you’re bundling cables, insulating wire splices, or providing strain relief for connectors, heat shrink tubing is the go-to solution for a neat and professional finish. Its ability to protect against moisture, chemicals, and abrasion makes it an indispensable asset in both household and industrial settings.

One of the most fascinating aspects of heat shrink tubing is its adaptability. It’s not just a simple insulator; it’s a game-changer for various DIY projects. For instance, if you’re an electronics hobbyist, using heat shrink tubing to insulate soldered connections can prevent short circuits and enhance the durability of your creations. In the automotive realm, it’s a lifesaver for protecting and bundling wires in the engine compartment, where exposure to heat and vibration is a constant threat. Moreover, with the rise of 3D printing, heat shrink tubing has found its way into the toolkit of makers and designers, providing a sleek and durable finish to 3D-printed parts. The possibilities are endless, and the results are always satisfying.

Now, let’s talk about the application process. Using heat shrink tubing is a breeze, even for beginners. All you need is a heat source, such as a heat gun or even a simple hairdryer. Once you’ve slid the tubing onto the desired area, applying heat will initiate the shrinking process, and within seconds, you’ll witness the tubing conforming perfectly to the surface. It’s like watching a superhero suit up for battle, but in the world of DIY, where the battle is against disorder and inefficiency. With a gentle touch of heat, the tubing transforms into a seamless, protective layer, ready to take on whatever challenges come its way.

Heat shrink tubing is more than just a mundane material; it’s a transformative tool that elevates the quality and longevity of DIY projects. Whether you’re a tech-savvy enthusiast, a crafty creator, or a professional in need of reliable cable management solutions, heat shrink tubing is a small investment that yields substantial returns. So, the next time you’re faced with a tangled web of wires or a fragile joint in your project, remember the magic of heat shrink tubing – a simple yet powerful ally in the pursuit of order and durability.

中文简体

中文简体

English

English