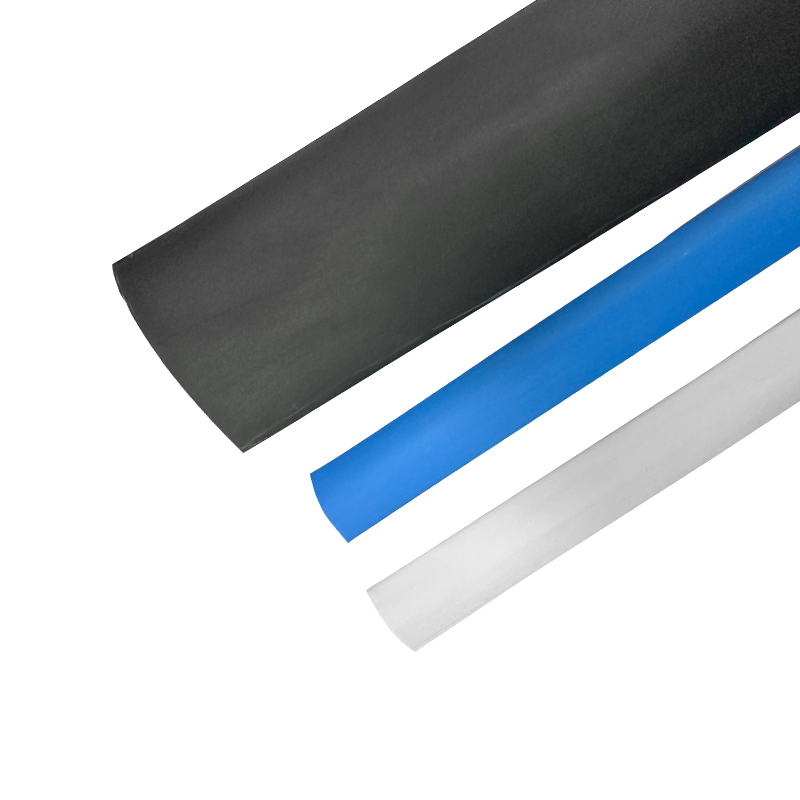

To improve the sealing effect of

double wall heat shrink tubing and ensure a reliable, long-lasting seal, you can follow these guidelines and best practices:

Proper Size Selection: Ensure that you choose the correct size and diameter of double wall heat shrink tubing for your application. The tubing should fit snugly over the object you want to protect or insulate. A tight fit is essential for an effective seal.

Surface Preparation: Clean the surface of the object to be covered with the tubing thoroughly. Remove any dirt, oil, grease, or contaminants that could interfere with the adhesion and sealing properties of the tubing. For some applications, abrasive cleaning or chemical cleaning may be necessary.

Adhesive Activation: When applying heat to the tubing, ensure that it shrinks evenly and completely around the object. Properly activating the adhesive lining is essential for creating a secure seal. Use a heat gun or other appropriate heat source with controlled temperature settings to avoid overheating or damaging the tubing.

Shrinking Process: Pay attention to the shrinking process. Make sure the tubing shrinks uniformly and conforms tightly to the contours of the object. Avoid leaving wrinkles or air gaps in the tubing, as these can compromise the seal.

Overlap and Layering: If necessary, overlap the tubing or use multiple layers to provide extra protection and enhance the sealing effect. Be sure to follow the manufacturer's recommendations regarding the maximum number of layers and overlap required for your specific application.

Cooling and Inspection: Allow the tubing to cool and set properly after the shrinking process. Inspect the seal to ensure there are no visible gaps or imperfections. If any issues are detected, consider reapplying heat and adjusting the tubing as needed.

Environmental Considerations: Choose double wall heat shrink tubing with the appropriate environmental and chemical resistance properties for your specific application. Different formulations are available for various environmental conditions, so ensure that the tubing is suitable for your needs.

Quality Tubing: Use high-quality double wall heat shrink tubing from reputable manufacturers or suppliers. Quality tubing is more likely to provide consistent sealing performance and adhere to industry standards.

Professional Installation: If you are unsure about the installation process or need to seal critical components, consider having the tubing applied by a professional with experience in heat shrink tubing installation.

Regular Inspection and Maintenance: Periodically inspect the sealed areas for signs of wear, damage, or degradation. Perform any necessary maintenance or repairs promptly to maintain the integrity of the seal over time.

By following these steps and guidelines, you can improve the sealing effect of double wall heat shrink tubing and ensure that it provides the protection and insulation required for your specific application. Proper installation and attention to detail are key to achieving a reliable and durable seal.

中文简体

中文简体

English

English