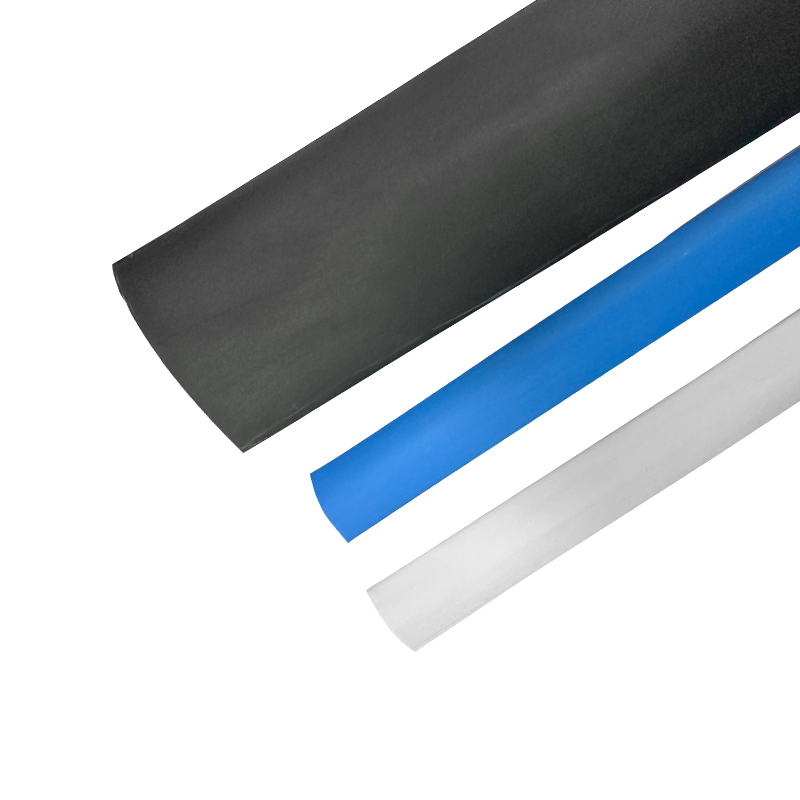

Double wall heat shrink tubing acts as a physical barrier by creating a protective, shrinkable sleeve around objects such as wires, cables, or connectors. This sleeve serves as a barrier against external elements and provides a number of protective functions. Here's how it acts as a physical barrier:

Encapsulation: Double wall heat shrink tubing is designed to fit snugly around the object it is intended to protect. When heated, it shrinks in size, conforming closely to the contours of the object. This encapsulation completely surrounds and isolates the object from its surroundings.

Sealing: As the tubing shrinks, it activates the adhesive lining on its inner layer. This adhesive melts and flows during the shrinking process, creating a secure, hermetic seal. This seal prevents external elements from infiltrating the protected area.

Conformity: Double wall heat shrink tubing is highly flexible and can conform to irregular shapes and surfaces. This means that it can effectively cover components with varying sizes and shapes, leaving no exposed areas for external elements to enter.

Mechanical Protection: In addition to sealing against dust, moisture, and contaminants, the tubing provides mechanical protection. It acts as a cushion against physical damage, abrasion, impact, and vibration. This helps prevent the wear and tear of wires and cables over time.

Environmental Protection: By encapsulating and sealing the enclosed object, double wall heat shrink tubing also offers protection against environmental factors such as UV radiation, extreme temperatures, and chemical exposure. It shields the object from these potentially damaging elements.

Corrosion Prevention: In applications where corrosion is a concern, the tubing's physical barrier prevents moisture and corrosive substances from coming into contact with the protected components, reducing the risk of corrosion.

The physical barrier created by double wall heat shrink tubing is crucial for safeguarding sensitive components and ensuring their long-term functionality and reliability. Whether in electrical, electronic, automotive, or industrial applications, this protective barrier helps maintain the integrity of the enclosed objects, extending their lifespan and reducing the need for maintenance or replacements.

中文简体

中文简体

English

English