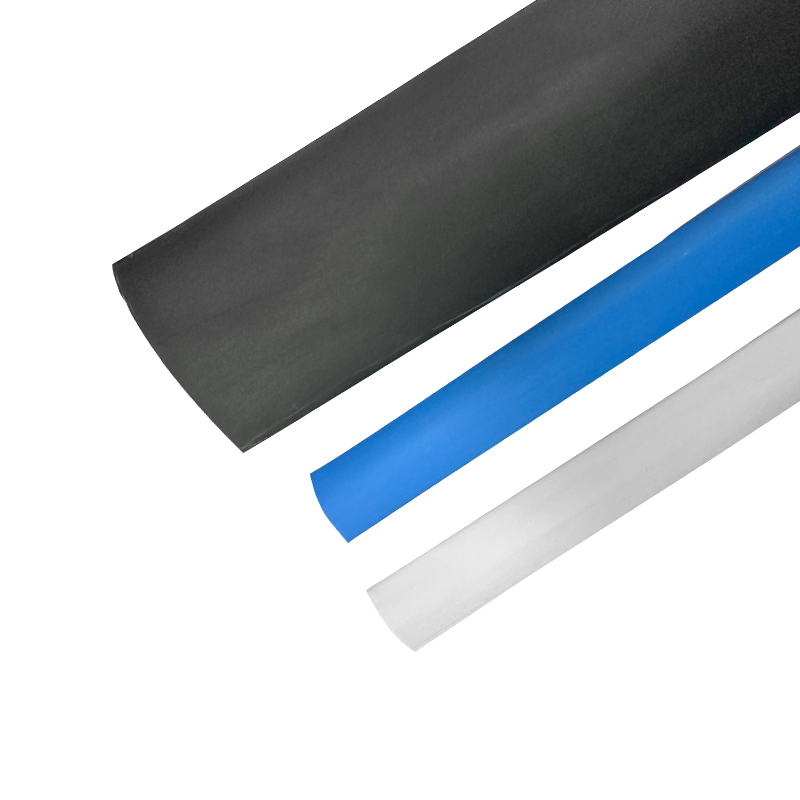

Double wall heat shrink tubing is an insulating material commonly used in the power, communications and pipeline industries. It has good insulation properties and sealing effects. Proper installation of double wall heat shrink tubing is critical to protecting the safe operation of cables, pipes, and other equipment. This article will introduce you how to properly install double wall heat shrink tubing to ensure a safe and reliable sealing or insulation effect.

Preparation

Before installing double wall heat shrink tubing, you first need to do some preparation work. Make sure the work area is clean and check that the double-walled heat shrink tubing used complies with relevant standards and requirements. In addition, you need to prepare appropriate tools, such as scissors, knives, heat guns, etc.

Measure and cut

Before installing double wall heat shrink tubing, you need to accurately measure the required length and use scissors or a knife to cut the double wall heat shrink tubing to the appropriate size. Make sure you cut evenly and avoid cutting too short or too long.

Preheating and casing

Before installing double wall heat shrink tubing, you need to use a heat gun to preheat the double wall heat shrink tubing to make it soft and stretchable. Then put the preheated double wall heat shrink tubing on the parts that need to be insulated or sealed, ensuring complete coverage and a tight fit.

heating and shrinking

After casing the double wall heat shrink tubing, use a heat gun to heat it evenly to ensure that the double wall heat shrink tube shrinks and fits tightly with the items being protected. Be careful to maintain proper heating distance and temperature to avoid overheating or burns.

Cool down and check

After the double wall heat shrink tubing has completely shrunk, let it cool naturally and inspect it. Make sure the double wall heat shrink tubing has no obvious gaps or bubbles and fits tightly to the item being protected. If any problems are found, the double wall heat shrink tubing should be reinstalled or replaced in time.

Proper installation of double wall heat shrink tubing is essential to protect the safe operation of cables, pipes and other equipment. Safe and reliable sealing and insulation can be ensured through steps such as preparation, measuring and cutting, preheating and casing, heating and shrinking, and cooling and inspection. During installation, be careful to use appropriate tools and maintain proper heating distance and temperature to avoid damaging the double-wall heat shrink tubing or the items being protected.

中文简体

中文简体

English

English